Compressed Air Solutions

Strong Stainless Steel

For reliable all-weather performance

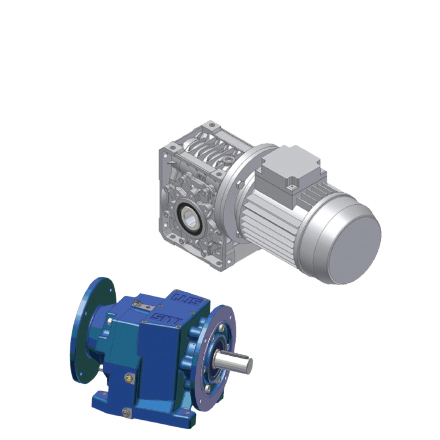

Industrial Brakes & Clutches,

Bearings, Transmission

Powering efficient industry through quality air and power solutions.

Probe Industrial Technologies

For Probe batteries and inverters

May 9, 2019

Next week will prove to be a busy week for local agricultural communities, with two highly anticipated events taking place simultaneously. The internationally-acclaimed NAMPO Harvest Day and Hartebeestloop Bonsmaras will draw crowds in both the Free State and Namibia, and Probe Corporation SA (Pty) Ltd, South Africa’s largest importer of premium, maintenance-free, fit and forget batteries and a leader in rotating electrics, will be present at both events.

June 11, 2018

The variety, flexibility and efficiency of LED lighting is unmatched, offering unprecedented opportunities to increase productivity in farming applications at a fraction of the cost of traditional incandescent and HID lighting. LEDs are also friendlier to the environment, an important consideration for farmers, as they don’t use glass bulbs, pressurised gases, toxic chemicals or burning filaments, instead emitting light by flowing electrical energy through a semiconductor.

June 11, 2018

Compressed air is a vital utility used in countless ways to benefit everyday life. While those in manufacturing and industrial plants recognize the ‘plant workhorses’ importance as a source of process and instrument air, most people associate compressors with the small compressor in their garage used to inflate tires. They do not realize that compressed air is the energy of choice to power a great variety of applications. Probe’s Petrus Pretorius explains.